Flow meter play a crucial role in industries where accurate measurement of fluid flow is essential for process control and optimization. As technology continues to evolve, flow meter innovations have paved the way for precision and optimization in various sectors. This article explores the latest advancements in flow meter technology, highlighting their significance in achieving precise measurements and optimized operations. From understanding different types of flow meters to examining the challenges faced by traditional systems, we will delve into the cutting-edge developments that are revolutionizing the field. Additionally, real-world applications and case studies will showcase the practical benefits of these innovations. By the end, we will uncover the potential challenges and considerations in implementing these advancements and explore the future trends that are shaping the landscape of flow meter innovations.

Understanding Flow Meters

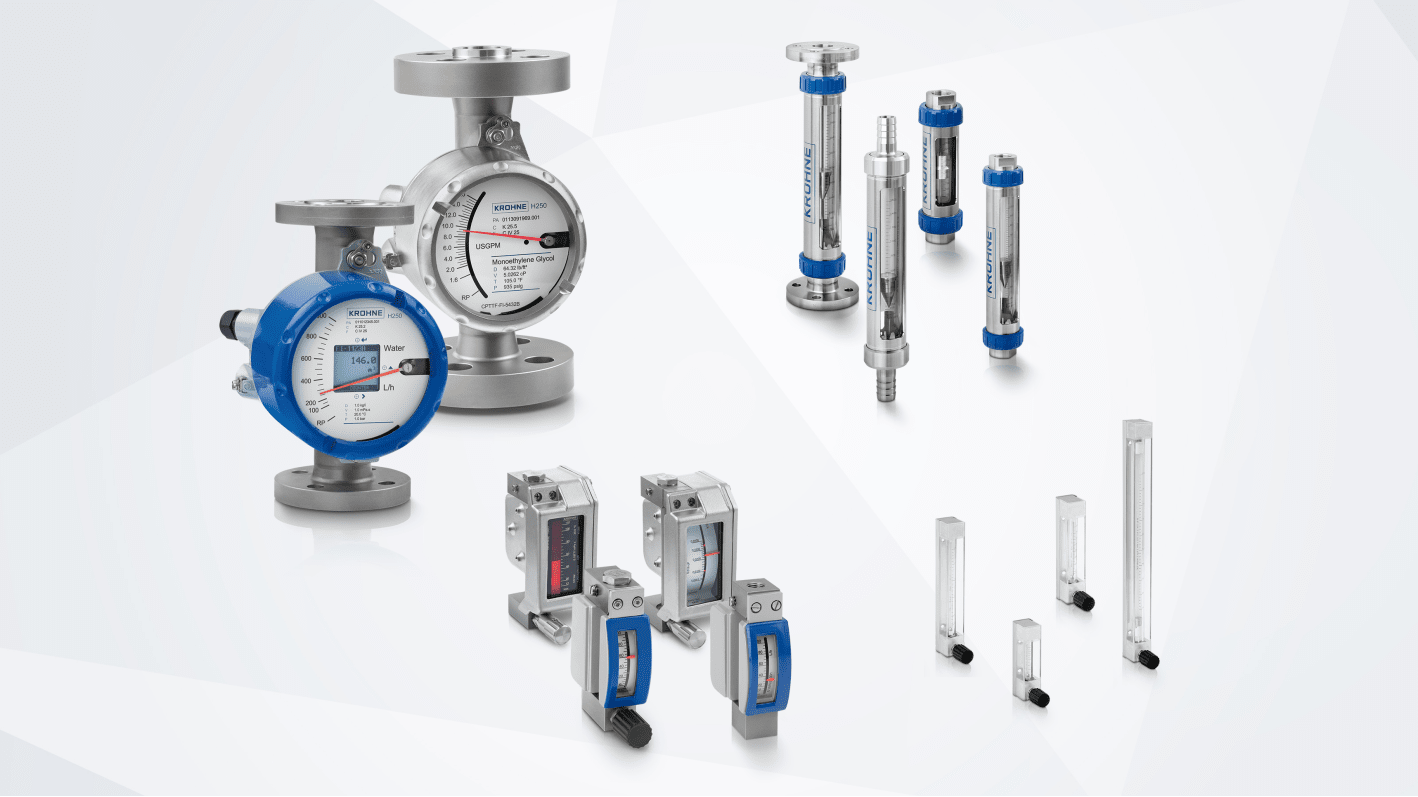

Before delving into the innovations, it is important to grasp the fundamental concepts of flow meters. Flow meters are devices used to measure the rate of flow of a fluid or gas in a pipeline or system. They come in various types, each catering to specific applications and measurement techniques. The different types include differential pressure flow meters, positive displacement flow meters, velocity flow meters, mass flow meters, ultrasonic flow meters, and magnetic flow meters. These devices rely on different principles, such as pressure differentials, volumetric displacement, velocity measurement, or magnetic induction, to accurately determine the flow rate.

Accurate Flow Measurement and Its Significance

Accurate flow measurement is of paramount importance in industries such as oil and gas, chemical manufacturing, water management, and more. It enables precise process control, ensuring that operations are optimized for efficiency and productivity. Flow meters provide valuable data for monitoring and maintaining operational parameters within desired limits. Accurate flow measurement also contributes to cost reduction, as it helps in resource optimization, prevents wastage, and minimizes energy consumption. Furthermore, it plays a crucial role in ensuring environmental compliance and safety standards, as precise flow measurements enable effective monitoring of emissions and leaks.

Challenges in Flow Measurement

Despite their importance, traditional flow meters have encountered several challenges. One common issue is the susceptibility to inaccuracies caused by factors like fluid properties, varying flow rates, and environmental conditions. Traditional flow meters may also experience pressure drops, leading to energy losses and decreased efficiency. Additionally, some flow meters are intrusive and can disrupt the flow path, causing undesirable effects on the system. Furthermore, maintenance and calibration requirements can be cumbersome and time-consuming, impacting overall operational effectiveness. These challenges have necessitated the development of innovative flow meter solutions.

Innovations in Flow Meter Technology

To address the limitations of traditional flow meters, the industry has witnessed remarkable advancements in flow meter technology. These innovations focus on enhancing measurement accuracy, integrating Internet of Things (IoT) and smart technology, and offering non-intrusive solutions.

New flow meter developments have significantly improved measurement accuracy, reducing uncertainties associated with varying fluid properties and flow conditions. Cutting-edge sensing mechanisms, such as advanced pressure sensors, ultrasonic transducers, or magnetic field sensors, enable precise and reliable flow measurement.

The integration of IoT and smart technology has revolutionized flow meter applications. Flow meters equipped with connectivity features allow real-time monitoring, remote data collection, and analysis. This enables predictive maintenance, optimized performance, and proactive decision-making for process improvement.

Non-intrusive and clamp-on flow meter solutions have gained traction due to their advantages in terms of installation, maintenance, and system compatibility. These innovative meters can be easily retrofitted onto existing pipelines without disrupting the flow, minimizing downtime and operational interruptions.

Benefits of Flow Meter Innovations

The innovations in flow meter technology bring numerous benefits to

industries relying on accurate flow measurement. These benefits include:

Enhanced Precision in Flow Measurement: The advanced sensing mechanisms and improved calibration techniques in innovative flow meters result in highly accurate and reliable flow measurements. This precision allows industries to make informed decisions based on precise data, leading to optimized processes and improved overall performance.

Optimized Process Control and Efficiency: Accurate flow measurement enables industries to fine-tune their processes, ensuring optimal flow rates and maintaining desired operational parameters. By closely monitoring flow rates, industries can identify inefficiencies, minimize waste, and optimize resource allocation, leading to increased productivity and reduced costs.

Cost Reduction and Resource Optimization: Accurate flow measurement plays a crucial role in identifying areas of waste and inefficiency in fluid or gas systems. By accurately measuring flow rates, industries can minimize energy consumption, reduce raw material waste, and optimize resource utilization, ultimately leading to cost savings and improved profitability.

Improved Environmental and Safety Standards: Precise flow measurement facilitates effective monitoring of emissions, ensuring compliance with environmental regulations. It also enables early detection of leaks or abnormal flow patterns, enhancing safety measures and preventing potential hazards in industrial processes.

Case Studies: Real-World Applications

To understand the practical benefits of flow meter innovations, let’s explore real-world applications in various industries:

- Flow Meter Innovations in Oil and Gas Industry: In oil and gas production, accurate flow measurement is crucial for custody transfer, well testing, and optimizing production rates. Advanced flow meters provide precise measurements, enabling operators to monitor and control flow rates accurately, leading to efficient resource allocation and reduced operational costs.

- Flow Meter Solutions in Chemical Manufacturing: Chemical manufacturing processes often involve complex fluid systems with stringent requirements for accurate flow measurement. Innovations in flow meter technology offer improved accuracy, allowing precise control over chemical flows, enhancing product quality, and minimizing waste.

- Flow Meter Applications in Water Management: Flow meters are vital in water management systems for measuring water consumption, detecting leaks, and optimizing water distribution. Advanced flow meters with IoT integration enable real-time monitoring of water flow rates, facilitating efficient water resource management and conservation efforts.

Implementation Challenges and Considerations

While flow meter innovations bring numerous benefits, their successful implementation requires careful consideration of several factors:

Compatibility and Integration with Existing Systems: Integrating new flow meter technology with existing infrastructure and control systems can pose challenges. Industries need to ensure compatibility and seamless integration to avoid disruptions and maximize the benefits of the new technology.

Training and Education for Operators: Operators and maintenance personnel need to be trained on the installation, operation, calibration, and maintenance of the new flow meters. Proper training ensures accurate readings, reliable performance, and timely troubleshooting.

Maintenance and Calibration Requirements: Innovative flow meters may have specific maintenance and calibration requirements to maintain their accuracy and reliability. Establishing proper maintenance schedules and adhering to calibration procedures are essential for long-term performance and optimization.

Future Trends in Flow Meter Innovations

The field of flow meter innovations continues to evolve, driven by advancements in sensor technology, data analytics, and connectivity. Future trends include:

- Emerging Technologies and Techniques: Developments in nanotechnology, advanced materials, and miniaturized sensors are expected to enhance the precision, sensitivity, and durability of flow meters.

- Industry-Specific Solutions: Flow meter innovations tailored to specific industries, such as pharmaceuticals, food and beverage, and renewable energy, will address unique measurement challenges and optimize processes.

- Potential Impact on Various Sectors: As flow meter technology advances, its applications are likely to expand to sectors beyond traditional industries, including healthcare, environmental monitoring, and smart cities.

Conclusion

Flow meter innovations are revolutionizing industries by providing precise measurements, optimizing processes, and reducing costs. These advancements enable enhanced control over fluid and gas flows,

resulting in increased efficiency, improved resource management, and adherence to environmental and safety standards. Real-world applications in sectors like oil and gas, chemical manufacturing, and water management demonstrate the practical benefits of these innovations.

However, implementing flow meter innovations requires careful consideration of compatibility, training, maintenance, and calibration. Industry professionals must stay informed about emerging technologies and industry-specific solutions to leverage the full potential of flow meter innovations.

As technology continues to advance, the future of flow meter innovations holds exciting possibilities. Emerging technologies, industry-specific solutions, and expanded applications across sectors will further enhance flow meter precision, efficiency, and optimization. By embracing these advancements, industries can navigate the path to precision and optimization, unlocking new levels of productivity and sustainability.